Advanced Automation Awaits

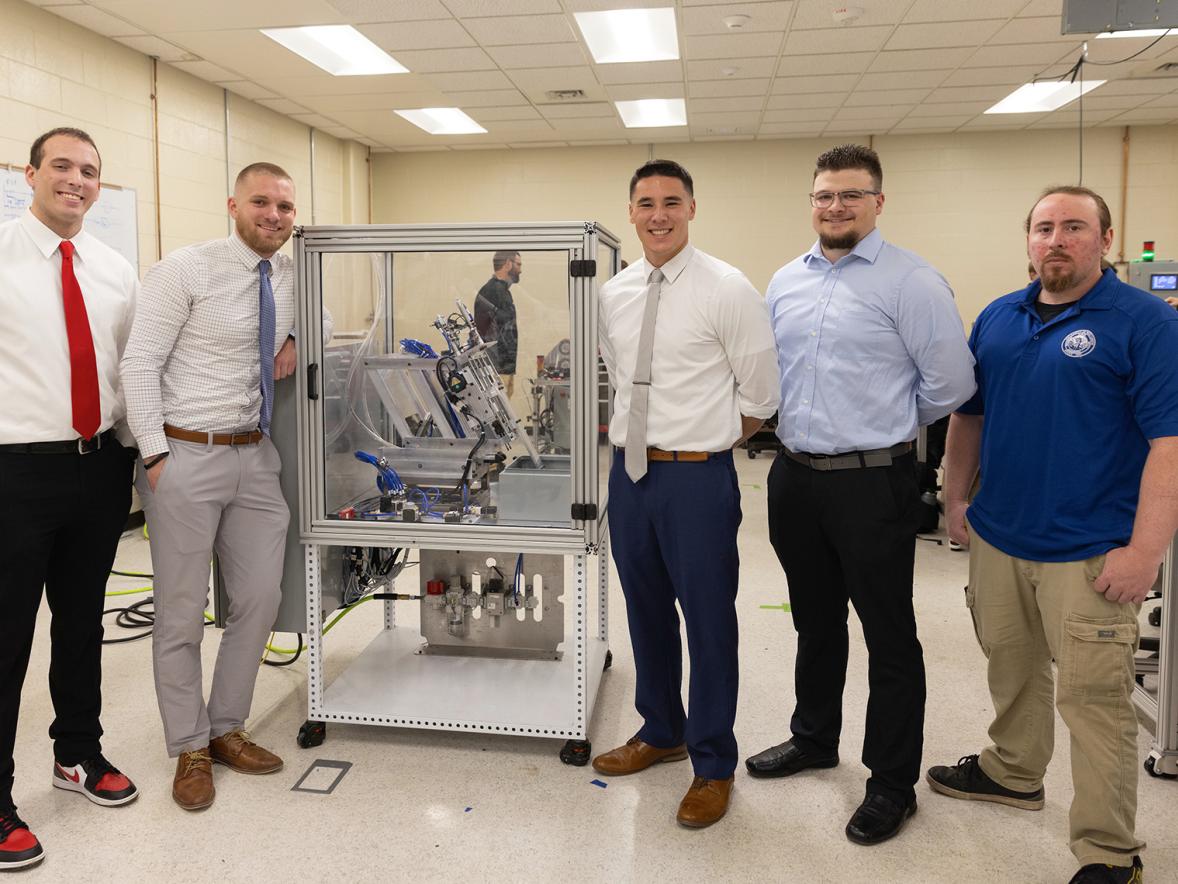

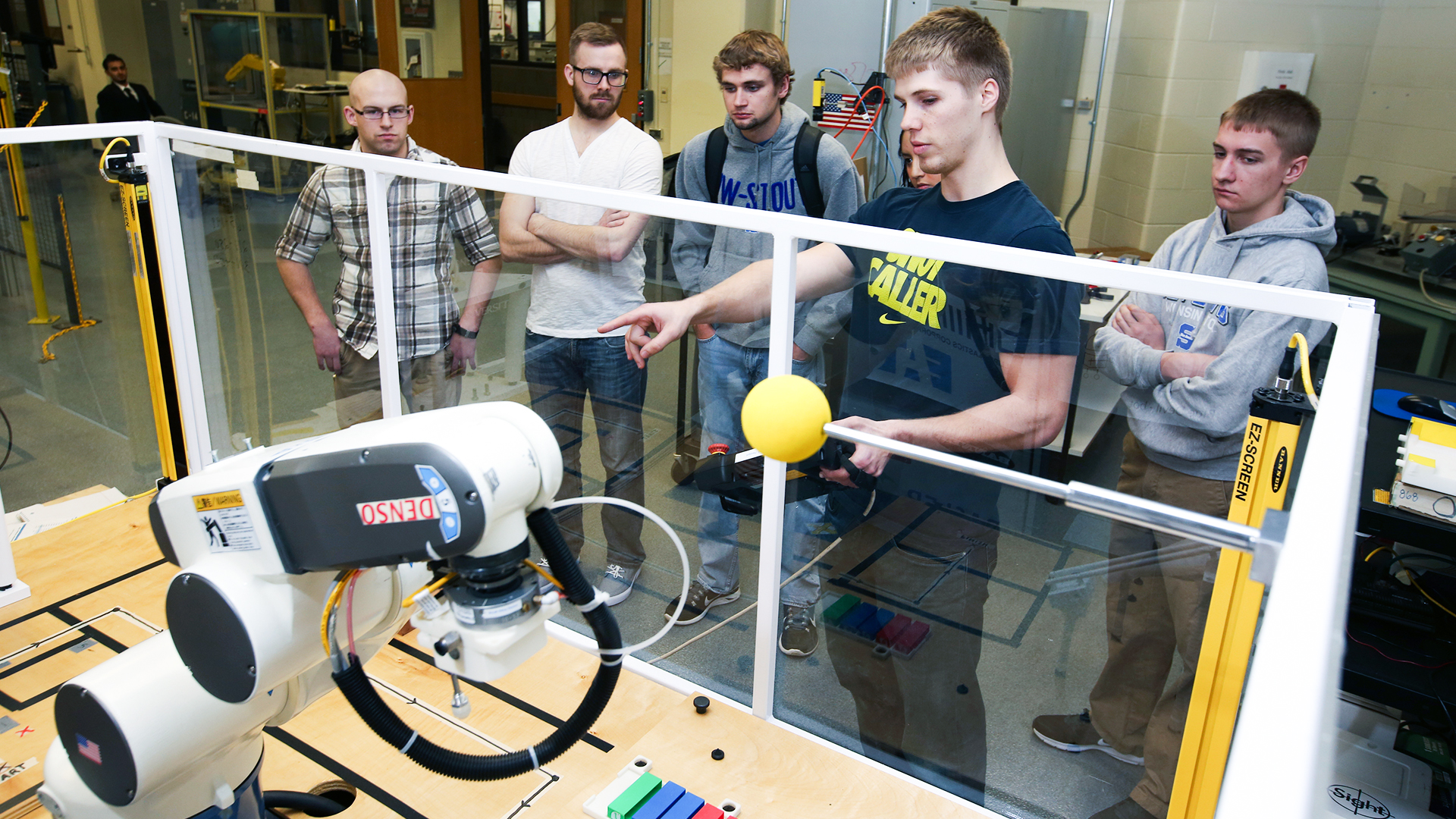

At UW-Stout, our state-of-the-art robotics lab exemplifies our commitment to hands-on, industry-standard education. With over half a million dollars in cutting-edge equipment, continually expanding through donations and partnerships, the lab offers unparalleled opportunities for applied learning. Students in technology, manufacturing, mechanical, and plastics engineering programs engage with advanced robotic systems, learning essential skills such as safety protocols, motion planning, and offline programming. Advanced coursework includes working with vision systems, PLCs, and mobile autonomous robots, preparing students for real-world challenges in robotics and automation.

Degrees That Do More in Our Lab.

Robotics Lab Equipment

The UR3e Collaborative Robot, a compact table-top robot designed for light assembly tasks, provides students with hands-on experience training and operating a collaborative robotics. At UW-Stout, you will learn the nuances of operating and programming this advanced robot, gaining automation and robotics industry knowledge.

The FANUC M-1iA/0.5A robot, a compact and lightweight machine, excels in precision tasks such as pick and place, assembly, and material handling. At UW-Stout, students will experience hands-on learning with this high-speed automation robot, preparing them for careers in advanced manufacturing and robotics.

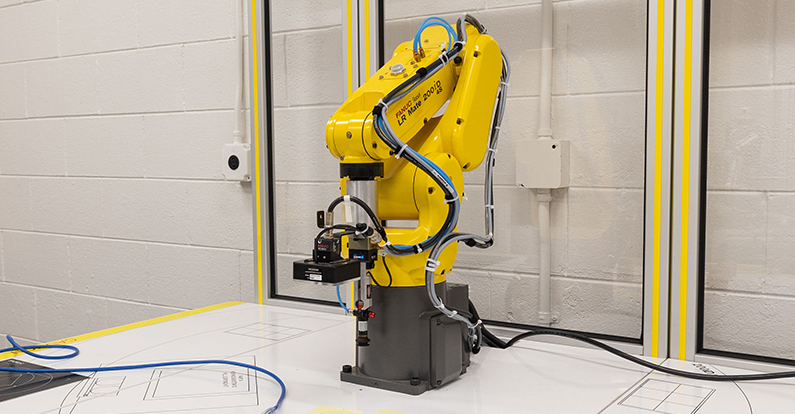

The FANUC LR Mate 200iD robot is a versatile and compact robot designed for various tasks including assembly, material handling, and machine tending. At UW-Stout, students will gain hands-on experience with this highly adaptable robot, learning to optimize its performance for precision operations.

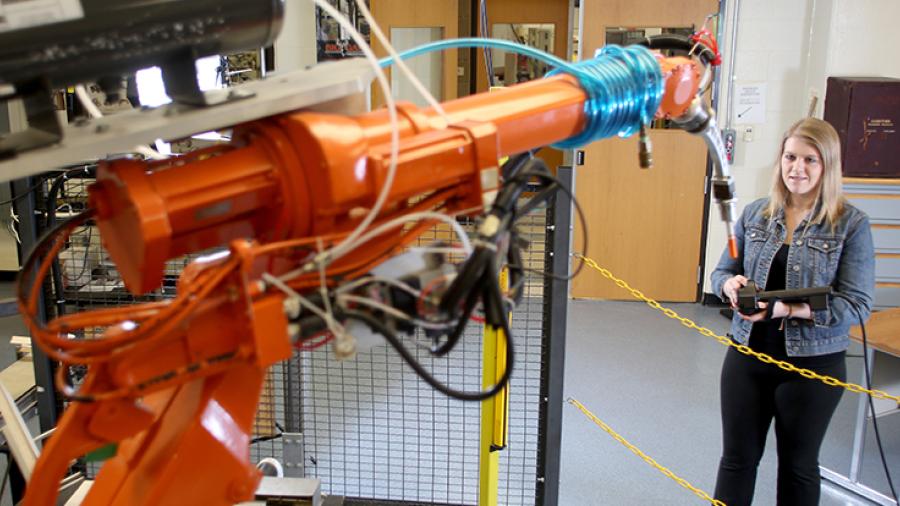

The ABB 1RB 2600 robot is engineered for precision in tasks such as pick and place, assembly, and material handling. At UW-Stout, students will gain hands-on experience with this lightweight robot, which handles tasks with meticulous accuracy and supports payloads up to 0.5 kg, making it ideal for high-speed automation in confined spaces.

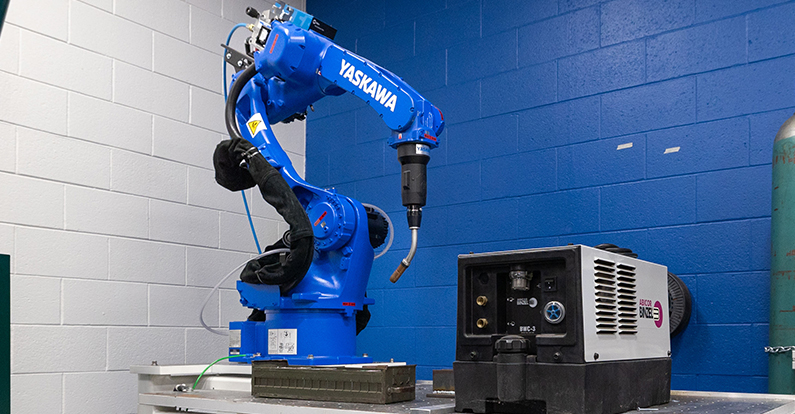

The six-axis Yaskawa AR1440 Welding Robot offers fast and precise performance, enhancing productivity in arc welding applications. At UW-Stout, students will gain practical experience with this advanced robot, which features a slim profile for high-density placement, a contoured arm for easy access in confined spaces, and a symmetric wrist for equal torch access on both sides, preparing them for careers working with welding and automation robots.