Tensile Testing Machine

This machine tests how strong and stretchy packaging materials are. It helps us make sure the materials can handle different stress conditions and meet strength and flexibility standards.

In the Packaging Materials Lab, the science of packaging is brought to life through rigorous analysis and innovative technology. This state-of-the-art laboratory is a core part of our renowned Packaging Program, providing students with hands-on experience using advanced equipment and testing methods that are leading the industry forward.

In the lab, students utilize advanced equipment to test packaging durability and sustainability. The curriculum spans box crush, burst, tear, tensile, and water durability, offering insights into material strength, flexibility, and usability properties. With an emphasis on ergonomic design, these tests ensure packaging meets both everyday demands and best practices in usability. This hands-on approach equips students with the skills to develop robust, user-friendly packaging solutions.

This machine tests how strong and stretchy packaging materials are. It helps us make sure the materials can handle different stress conditions and meet strength and flexibility standards.

This tool measures how resistant packaging materials are to tearing. It helps us see how easily a material can tear from a small cut, making sure packaging can handle real-world stresses and stay durable during transport.

This device measures how strong packaging materials are when squeezed or stacked. It helps ensure that packaging can protect products during storage and transport by testing their strength.

This device measures how much pressure packaging materials can take before bursting. It helps make sure packaging is strong enough to handle shipping and handling without breaking.

This tool tests how packaging materials behave in wet conditions. It helps us see how water-resistant the materials are and ensures they stay protective even when exposed to moisture.

This device measures how stiff and strong packaging materials are when bent. It helps us ensure packaging can keep its shape and protect contents during transport.

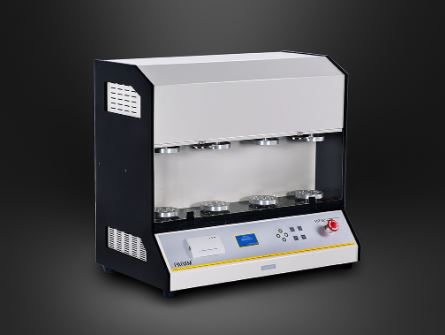

This machine tests how slippery packaging materials are. It measures both still and moving friction to help us choose the best materials for easy processing, handling, and transport.

This machine tests how slippery packaging materials are. It measures both still and moving friction to help us choose the best materials for easy processing, handling, and transport.

The lab equipment allows students to gain sealing and layering proficiency, enhancing package integrity and shelf life. Utilizing UV and visual light detection, the curriculum supports the creation of protective packaging solutions. Through hands-on testing, including strength and tensile assessments, students acquire a deep understanding of material durability and ergonomic design, preparing them for industry challenges and promoting user-friendly packaging development.

This tool tests how packaging materials react to UV light. It helps us ensure that packaging can withstand sunlight or UV exposure without losing strength or color.

This tool measures how packaging materials absorb and transmit UV and visible light. It helps us ensure packaging maintains color, transparency, and protects against harmful UV light.

This tool seals packaging trays to test how well they close. It ensures that packaging keeps products safe from contaminants and helps them stay fresh.

This tool applies even coatings to packaging materials. It tests how different coatings affect strength, durability, and appearance, helping develop better protective and attractive packaging.

This tool tests the overall strength and reliability of packaging materials. It ensures packaging can maintain its structure and protect contents under stress, meeting high safety and quality standards.

This tool creates heat seals in packaging materials. It tests how effective and durable these seals are, ensuring airtightness and quality, especially for food and pharmaceutical packaging.

The advanced testing equipment allows students to explore packaging's defense against gas, moisture, and extreme conditions. Key tests include oxygen and water vapor penetration, gas analysis, and environment testing. This focus equips students with a detailed understanding of packaging resilience, aiming for the highest industry standards in protection and durability.

This tool measures how much oxygen can pass through packaging materials. It helps ensure packaging protects products from oxygen, maintaining their quality and shelf-life.

This tool measures how much water vapor can pass through packaging materials. It helps ensure packaging resists moisture, keeping products dry and maintaining their quality and longevity.

This tool analyzes the gases inside packaging. It ensures the right balance of gases like oxygen and carbon dioxide, helping to extend shelf life and maintain product quality.

This tool simulates different weather conditions to test how packaging materials handle various temperatures and humidity levels. It helps ensure the packaging is durable and reliable.

This tool detects leaks in packaging using carbon dioxide. It ensures packaging is airtight, keeping perishable goods safe and extending their shelf life.

This tool measures how quickly oxygen passes through packaging materials. It helps ensure packaging protects products from oxidation and spoilage, keeping them fresh and high-quality.

Our Packaging Materials Lab a cornerstone of the packaging program, boasts an array of industry-standard equipment, generously donated by Prent Corporation. This state-of-the-art machinery includes advanced systems for tensile testing, coefficient friction analysis, as well as cutting-edge instruments for assessing oxygen permeability and water vapor transmission rates. The lab's comprehensive suite of tools ensures that students are not only learning with the same high-grade equipment found in professional settings but also gaining a deep understanding of the scientific and engineering principles essential for developing robust packaging solutions.