Empowering Engineering Solutions Through 3D Printing

At UW-Stout, our Additive Manufacturing Lab supports all our engineering programs by providing the cutting-edge 3D printing technology to model and print parts and prototypes that address professional challenges. Featuring a range of advanced 3D printers, including Stratasys, Markforged, and Prusa models, this lab enables students to enhance their skills in 3D modeling, material selection, and the printing process—from design to prototype—as they develop the ingenuity and expertise to tackle modern engineering challenges with confidence.

Dive Deeper Into the Additive Manufacturing Lab's Equipment

The Creality Ender 3 is a popular 3D printer known for its affordability and reliability. It offers a hands-on learning experience in basic 3D printing processes, including setup and calibration. This printer is ideal for students to practice and refine their skills in additive manufacturing, from initial design to final print.

The Formlabs SLA printer uses Stereolithography (SLA) technology to create high-detail, precise resin prints. It provides students with the ability to produce complex geometries and smooth surface finishes, enhancing their understanding of high-resolution 3D printing techniques and material properties.

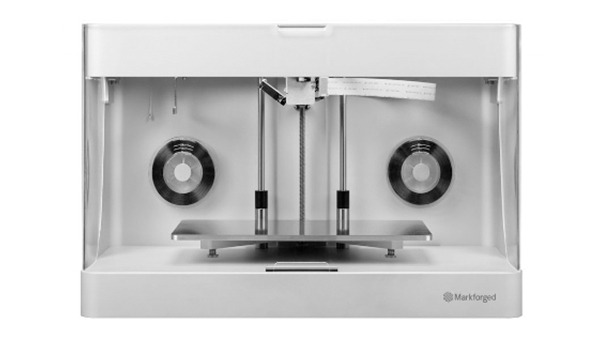

The Markforged 3D printer is designed for creating high-strength composite parts. It utilizes advanced composite materials, allowing students to produce durable, functional components. This printer is instrumental in teaching students about the applications of composite materials in engineering and manufacturing.

The Prusa i3 MK3S is a reliable and versatile open-source 3D printer. Known for its robust design and ease of use, this printer provides students with hands-on experience in 3D printing technology, including setup, calibration, and printing with various materials, fostering a practical understanding of additive manufacturing.

The Stratasys F170 is part of the F123 series, renowned for its precision and reliability in producing high-quality parts using Fused Deposition Modeling (FDM) technology. This printer supports both prototyping and production applications, offering a range of material options and user-friendly software, making it an essential tool for engineering students to develop industry-relevant skills.